Battery tenders are essential for maintaining optimal battery health, especially during periods of inactivity, ensuring reliable performance when needed, as of October 14, 2024.

What is a Battery Tender?

A battery tender, fundamentally, is a small charger used to maintain the charge of a lead-acid battery. Unlike a traditional battery charger that delivers a high current to quickly replenish a depleted battery, a tender provides a low, consistent current. This gentle approach prevents overcharging, a common issue that can damage batteries and shorten their lifespan.

Essentially, it “tends” to the battery, keeping it at its peak voltage. This is particularly useful for batteries in vehicles, motorcycles, boats, or any equipment stored for extended periods. As noted on November 1, 2024, understanding its function is key to proper use. It’s not about rapidly restoring a dead battery, but about maintaining a healthy one. The PowerLight system, while different, highlights the importance of consistent power delivery, a principle shared with battery tenders.

Why Use a Battery Tender?

Utilizing a battery tender offers significant advantages, primarily preventing the parasitic drain that occurs even when equipment is switched off. Modern vehicles, with their electronic systems, continuously draw power, slowly depleting the battery. A tender counteracts this, ensuring the battery remains fully charged and ready for use.

Furthermore, consistent maintenance extends battery life, saving you money on replacements. As experienced with the .75a Battery Tender Jr, insufficient charging can be a problem, highlighting the need for appropriate amperage. Avoiding a completely discharged battery is crucial, as deep discharges significantly reduce a battery’s capacity. Remember the safety advice from January 24, 2026: never charge a frozen battery! Proper tending also mitigates sulfation, a buildup of lead sulfate crystals that hinders performance. Ultimately, a tender provides peace of mind, guaranteeing reliable starting power.

Understanding Battery Tender Types

Battery tenders range from standard models offering constant voltage to smart tenders with multi-stage charging, optimizing battery health and preventing overcharging issues.

Standard Battery Tenders

Standard battery tenders, often the more economical option, deliver a continuous, unregulated voltage to the battery. These chargers are simpler in design and operation, making them straightforward to use for basic maintenance. However, they lack the intelligent charging capabilities of their smart counterparts.

Because of their constant voltage output, standard tenders are best suited for batteries that are already fully charged or nearly so. Prolonged use with a deeply discharged battery can lead to overcharging and potential damage, reducing the battery’s lifespan. It’s crucial to monitor the battery’s condition when using a standard tender, checking for excessive heat or gassing.

These tenders are generally appropriate for maintaining batteries in vehicles or equipment that are used frequently, providing a trickle charge to offset self-discharge. They are not ideal for long-term storage or for reviving severely depleted batteries, where a smart tender’s staged charging process is far more effective and safe.

Smart Battery Tenders (with Charging Stages)

Smart battery tenders utilize a multi-stage charging process, offering a significantly more sophisticated approach to battery maintenance. These chargers automatically cycle through phases – typically bulk, absorption, and float – to optimize charging and prevent overcharging, as noted on November 1, 2024.

The bulk stage rapidly replenishes the battery’s charge, while the absorption stage fine-tunes the voltage to maximize capacity. Finally, the float stage maintains the battery at a full charge without causing damage. This intelligent system makes smart tenders ideal for long-term storage and reviving deeply discharged batteries.

Many smart tenders also include features like automatic voltage detection and short-circuit protection, enhancing safety and convenience. They are capable of assessing battery condition and adjusting the charging process accordingly, ensuring optimal performance and extending battery life. They are a superior choice for most applications.

Junior vs. Plus Models – Key Differences

Battery Tender Junior and Plus models cater to different battery capacities and charging needs. The Junior, with its lower amperage (typically 0.75A), is best suited for smaller batteries like those found in motorcycles, ATVs, and personal watercraft, as experienced on January 24, 2026.

Conversely, the Plus model delivers a higher amperage (usually 3A or more), making it ideal for larger batteries in cars, trucks, and boats. The Plus also often includes additional features like temperature compensation, which adjusts the charging voltage based on ambient temperature, improving battery health in varying climates.

Users found the .75a Battery Tender Jr sometimes took 1-2 days for a full charge, which is unacceptable for some. The Plus offers faster charging times for deeply discharged batteries. Choosing the right model depends on your specific battery size and charging requirements, ensuring efficient and effective maintenance.

Setting Up Your Battery Tender

Proper setup involves securely connecting the charger to the battery terminals – positive to positive, negative to negative – and positioning it safely, away from the elements.

Connecting to the Battery (Positive & Negative Terminals)

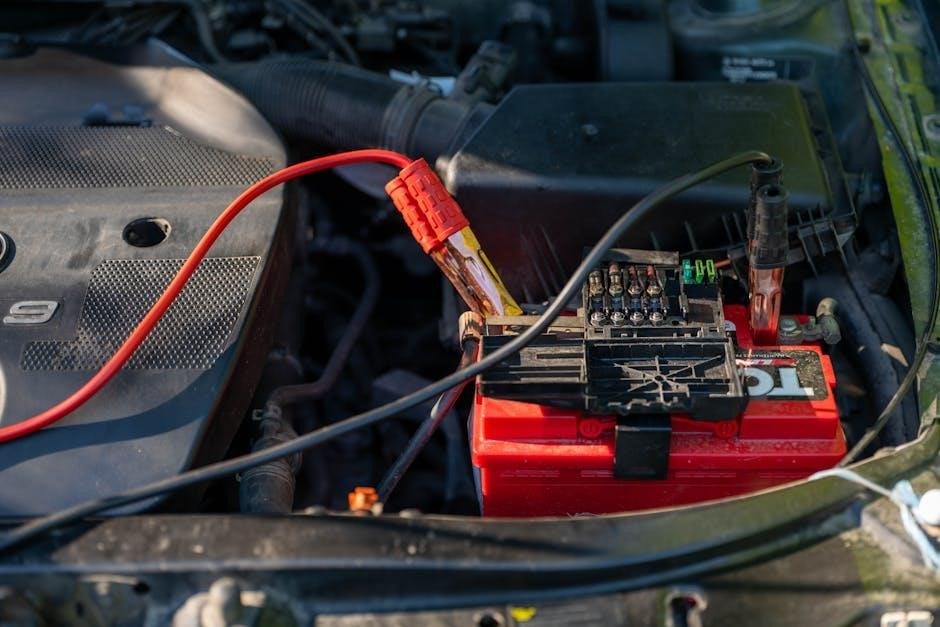

Establishing a secure connection is paramount when utilizing a battery tender. Begin by identifying the positive and negative terminals on your battery; these are typically marked with “+” and “-” symbols, respectively. Ensure the battery tender is switched off before initiating any connections to prevent potential short circuits.

Attach the red (positive) clamp of the battery tender to the positive terminal of the battery, ensuring a firm and clean contact. Subsequently, connect the black (negative) clamp to the negative terminal. A snug fit is crucial for efficient charging, but avoid over-tightening, which could damage the terminals.

Double-check the polarity – positive to positive, negative to negative – before switching on the charger. Incorrect polarity can cause irreversible damage to the battery and the tender. If the terminals exhibit oxidation, clean them thoroughly before connecting the clamps for optimal conductivity, as recommended on November 1, 2024.

Optimal Charger Placement & Environmental Considerations

Strategic placement of your battery tender is vital for both safety and performance. Position the charger as far away from the battery as the DC charger cables allow, minimizing potential hazards and ensuring adequate ventilation. Avoid placing the tender directly on flammable surfaces or near combustible materials;

Crucially, protect the charger from the elements. Never expose it to rain or snow, as this can create a significant electrical shock risk and damage the unit, as highlighted on October 14, 2024. Indoor use is highly recommended, or if outdoor use is unavoidable, ensure it’s sheltered and protected by a waterproof covering.

Maintain a well-ventilated area around the charger during operation to prevent heat buildup. Avoid extreme temperatures, and ensure the surrounding environment is dry and free from dust and debris. Proper placement contributes to a longer lifespan for both the charger and the battery.

Troubleshooting Common Issues

Initial checks involve verifying connections and settings; if problems persist, examine battery condition for old cells or reduced capacity, as of November 1, 2024.

Battery Not Charging – Initial Checks

First, meticulously inspect the connections to the battery terminals – positive and negative. Ensure they are clean, tight, and free from corrosion. Oxidized terminals significantly impede the charging process, preventing a proper electrical flow. A visual inspection is crucial; look for any visible damage to the charger cables themselves, such as fraying or cuts.

Next, confirm the charger is securely plugged into a functioning power outlet. Test the outlet with another device to rule out any electrical issues. Verify the charger’s indicator lights are illuminating, signaling it’s receiving power and attempting to charge. If no lights appear, the charger itself may be faulty.

Furthermore, double-check the battery’s voltage. A deeply discharged battery might initially appear unresponsive. If the battery is severely depleted, it may take a longer period to register a charge. Refer to the battery’s specifications to understand its voltage requirements and expected charging time. Remember to consult the battery supplier’s instructions for assessing battery condition.

Overcharging Concerns & Prevention

Modern battery tenders, particularly smart models, are designed to prevent overcharging through multi-stage charging processes. However, vigilance is still key. Regularly inspect the charger’s indicator lights to confirm it’s transitioning through the appropriate charging phases – typically bulk, absorption, and float.

If you suspect overcharging, immediately disconnect the battery tender. While less common with smart chargers, a malfunctioning unit could potentially damage the battery. A 60 Amp battery charger experiencing overcharging can be fixed within minutes, according to some sources, but prevention is preferable.

To minimize risk, avoid leaving a battery tender connected indefinitely. Periodic checks are recommended. Ensure the charger is appropriate for the battery type and capacity. Using an incorrect charger can lead to inefficient charging or, in severe cases, battery damage. Always prioritize safety and follow the manufacturer’s guidelines.

Dealing with Oxidized Battery Terminals

Oxidized battery terminals are a common issue hindering proper charging. Corrosion creates resistance, impeding the flow of current from the tender to the battery. The first step in troubleshooting a charging problem should be inspecting the terminals for oxidation, as noted in recent documentation.

To address this, disconnect the battery tender and the battery. Create a solution of baking soda and water, and gently scrub the terminals with a wire brush dipped in the solution. Rinse thoroughly with water and dry completely. A specialized battery terminal cleaner can also be used for effective results.

After cleaning, apply a thin coat of dielectric grease to the terminals to prevent future corrosion. Ensure a secure connection when reattaching the tender’s clamps. Clean connections are vital for efficient charging and maximizing battery life. Remember to check the contacts directly connected to the battery.

Battery Condition & Maintenance

Regular checks of battery health are crucial, especially for older batteries, to identify dead cells or reduced capacity, as recommended by battery suppliers on November 1, 2024.

Checking Battery Health (Old Batteries & Dead Cells)

Assessing the condition of an older battery is vital before relying on a tender for rejuvenation. If the battery is aged, carefully inspect it following the manufacturer’s guidelines; this often involves a load test to determine its remaining capacity. A significant drop in voltage during the load test indicates a weakened battery.

Dead cells within a battery can severely impede its performance and ability to hold a charge. While a battery tender can sometimes recover a slightly depleted battery, it generally cannot revive one with completely dead cells. Visual inspection might reveal bulging or corrosion around individual cells, signaling internal damage.

Furthermore, a battery tender won’t fix a battery that’s reached the end of its lifespan. Regularly monitoring the battery’s performance and replacing it when necessary is crucial for optimal system reliability, as suggested on November 1, 2024. Ignoring these signs can lead to unexpected failures and potential damage to connected equipment.

When to Replace a Battery

Determining when to replace a battery, even with consistent tender use, is crucial for reliable performance. If a battery consistently fails to hold a charge, despite regular maintenance, it’s a strong indicator of internal degradation. Repeatedly attempting to revive a failing battery can be counterproductive and potentially harmful.

Significant physical damage, such as cracks in the casing or noticeable swelling, necessitates immediate replacement. Corrosion around the terminals, even after cleaning, can suggest internal issues compromising the battery’s integrity. A battery exhibiting a short lifespan – requiring frequent charging even when not in use – is also a candidate for replacement.

Ultimately, if a battery consistently underperforms, fails load tests, or shows signs of physical damage, replacement is the most sensible course of action. Continuing to use a compromised battery can lead to system failures and potentially damage connected devices, as noted on November 1, 2024. Prioritize safety and reliability by replacing aging batteries promptly.

Safety Precautions

Always avoid charging frozen batteries and protect the charger from rain or snow to prevent electrical hazards, as emphasized on October 14, 2024.

Never Charge a Frozen Battery

Attempting to charge a frozen battery is extremely dangerous and can lead to severe consequences. A frozen battery contains water that expands as it freezes, potentially causing the battery case to crack or rupture. This can result in the release of corrosive battery acid, posing a significant hazard to your health and surroundings.

Furthermore, charging a frozen battery can generate flammable hydrogen gas, creating a risk of explosion. The internal resistance of a frozen battery is also significantly increased, which can damage the battery charger itself. Always ensure the battery is fully thawed before attempting to charge it with a battery tender.

Inspect the battery carefully for any signs of cracking or leakage before connecting it to the charger. If you suspect the battery is frozen, allow it to thaw naturally in a safe location, away from flammable materials. Never use external heat sources to thaw a battery, as this can exacerbate the risk of explosion. Prioritize safety and avoid any actions that could compromise the integrity of the battery or the charging process.

Avoiding Exposure to Rain or Snow

Protecting your battery tender and battery connection from the elements is crucial for safe and effective operation. Exposure to rain or snow can create a hazardous situation due to the electrical conductivity of water. This can lead to short circuits, damage to the charger, and potentially, electrical shock.

Always position the battery tender in a dry, sheltered location, away from direct rainfall or snowfall. If outdoor use is unavoidable, utilize a weatherproof enclosure specifically designed for battery chargers. Ensure all connections between the charger and the battery are secure and protected from moisture; Regularly inspect the cables for any signs of damage or corrosion.

Locate the charger as far away from the battery as the DC charger cables permit, minimizing exposure. Do not expose the charger to rain or snow, as stated on October 14, 2024. Prioritize safety by keeping electrical components dry and preventing water ingress into the system.